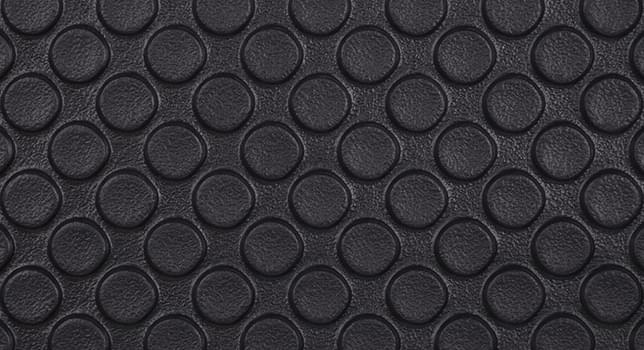

Rubber

Smithers rubber testing experts have many years of experience working with rubber materials, components, and products from a wide variety of industries. Our team can conduct industry standard tests or design a custom testing protocol to meet your unique needs.