Smithers provides an overview of environmental stress cracking for polymer materials, and how test programs can help reduce or even prevent failure.

What is Environmental Stress Cracking (ESC)?

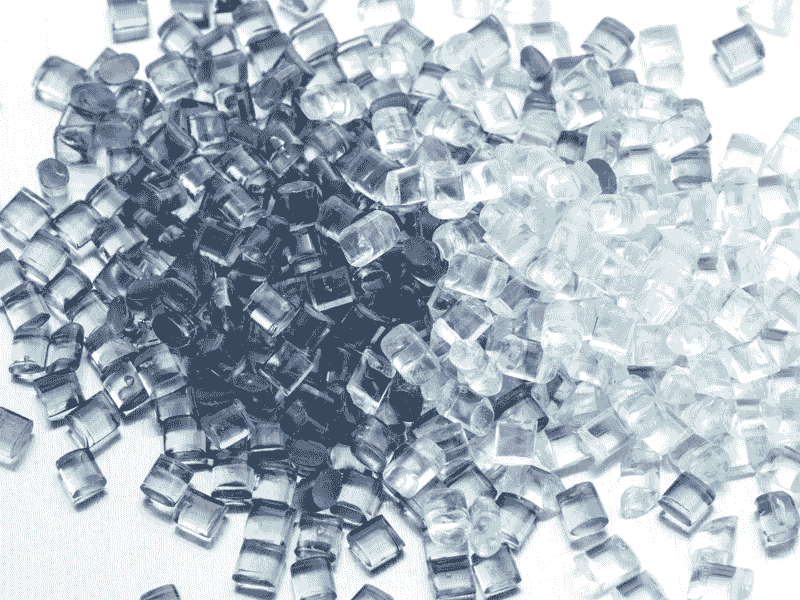

ESC is the occurrence of cracking in a polymer by contact with a liquid or vapour environment and stress. There is no chemical degradation, but the presence of the ESC agent accelerates the effect of stress by a purely physical mechanism; resulting in microscopic crazes, which eventually form cracks and the failure of the component. It should also be noted that stress cracking in ABS and polycarbonate has been reported in air – in the presence of stress only.

What causes stresses in plastics?

Stresses in plastics are present by design in a structural component, or inadvertently during molding or assembly of the part. In a well-designed part the stresses are kept to a minimum or eliminated. The resistance of the polymer to expected potential ESC agents should have been assessed at the design state and these are sometimes termed as “primary environments”.

Is Environmental Stress Cracking (ESC) a problem?

Many cases of failure investigations have failures due to ECS. The failures involve the presence of what are classed as “secondary environments”, these are ESC agents not considered during design, but have inadvertently come into contact with the item causing it to fail.

What types of fluids cause plastics to fail prematurely?

It’s estimated that 90% of these failures involve glass amorphous thermoplastics in contact with “secondary environments” such as:

- Paints

- Adhesives

- Cleaning agents

- Lubricants

- Plasticizers

- Inks

- Aerosol sprays

- Leak detection fluid

- Fruit essences

- Vegetable oils.

How do Smithers undertake ESC testing?

Testing involves applying a known stress to the polymer under tests and exposing it to the relevant ESC environment. Short term tests under relatively high strains will induce catastrophic failure within hours or a few days. For lower stresses and less aggressive environments, it is recommended that properties such as impact or tensile strength are measured before and after exposure.

The most common method of applying the stress is by bending a strip of plastic over a curved former which has a radius appropriate for the desired surface stress in the test strip. This approach has been adopted by national and international standards for example:

- ASTM D 543-14 Standard Practices for Evaluating the Resistance of Plastics to Chemical Reagents.

- ISO 22088-3:2008 Plastics – Determination of resistance to environmental stress cracking (ESC) Part 3: Bent Strip Method.

How can ESC testing help resolve premature failure?

Undertaking an ESC investigation during the materials selection stage will help designers evaluate thermoplastics against anticipate potential ESC agents, and therefore eliminate any unsuitable polymer materials. Smithers also offers a failure analysis service, and where ESC is identified as the cause can offer advice on alternative polymers or changes to the component design.

Find out more about our environmental stress cracking testing.