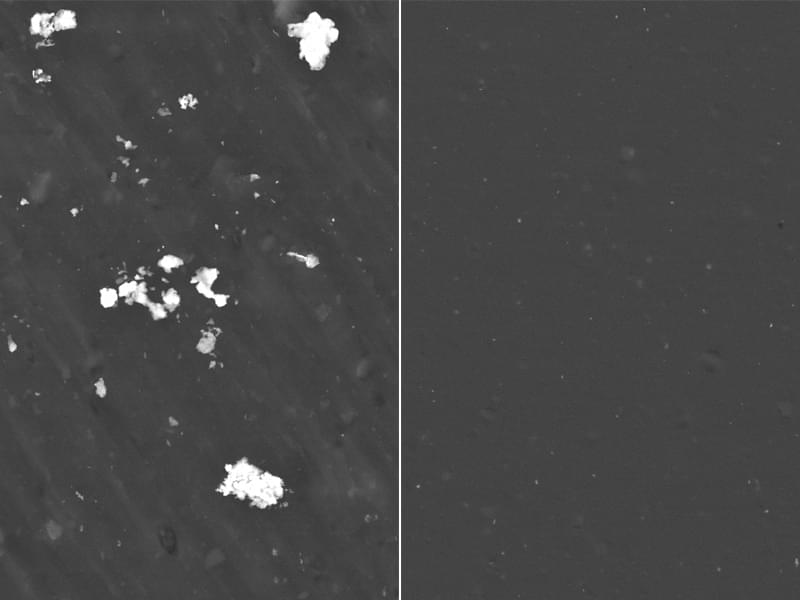

Smithers recently invested in a new one-liter

intermesh mixer for its U.S.-based chemistry lab in Akron, Ohio. The new mixer can handle high-viscosity stocks and compounds containing raw materials that tend to be hard to disperse.

The new mixer delivers improved distributive, dispersive, and reactive mixing and can achieve results with fewer passes. Intermesh rotors offer more surface area and contact points inside the mixing chamber, both against the walls of the chamber and between the rotor blades. This allows for increased shear and better temperature control than could be achieved in a tangential mixer. Using an intermesh mixer also improves the effectiveness of the hydrophobation chemical reaction of the organosilane with the silica, an important benefit considering the fact that silica is notoriously difficult to mix with natural

rubbers.

The tire industry is trending toward increased silica use in

passenger and light truck tires. Silica-based tire treads handle better in rainy weather due to improved wet traction and contribute to better fuel economy due to lowered rolling resistance.

“

Intermesh mixing has become the standard for silica-based treads,” said Dr. Jim Popio, Vice President for North America, Materials Science & Engineering, Smithers. “We’re committed to investing in upgrades that allow our customers to stay ahead of industry trends. This addition to our lab will help us to better serve raw materials suppliers to the tire industry.”

The new mixer allows

raw material suppliers to test prototype materials in small batches before investing in large-scale production. It can be used to look at properties of a supplier’s materials in silica treads, predict real-world performance, and benchmark experimental materials versus standard materials that are currently on the market. The mixer can also test a new material’s ability to scale up to production volume and support the qualification of new production plants for existing materials.

“This new investment gives our clients access to important data without having to invest in the machine and expertise needed to conduct this kind of testing in-house,” said

Christine Domer, General Manager, Akron Labs. “We look forward to helping our customers make strides in the industry and achieve their business goals.”

Read an interview with in-house mixing expert Scott Sarah >