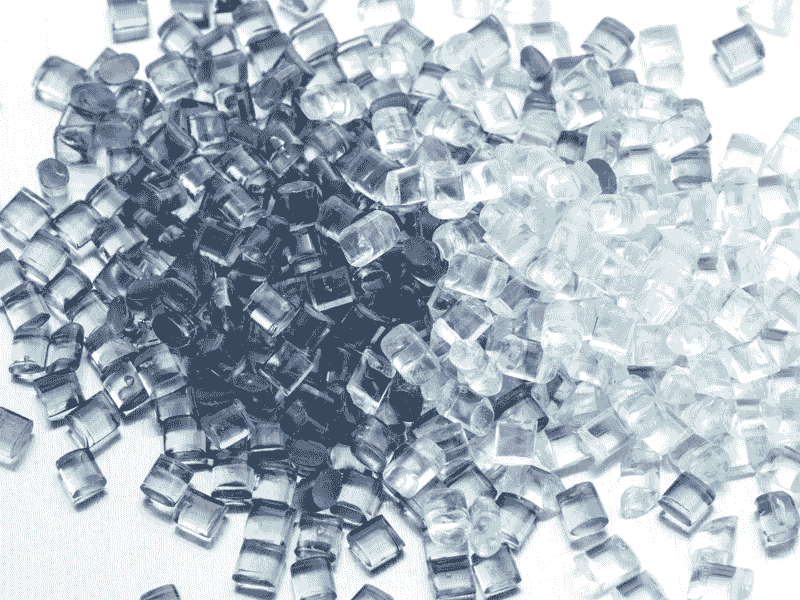

Fluid Contamination and Susceptibility Testing | Fluid Compatibility Testing

Smithers provides fluid compatibility and fluid immersion testing to a number of recognized industry standards. Our team can also support with designing custom protocols to meet your specifications.