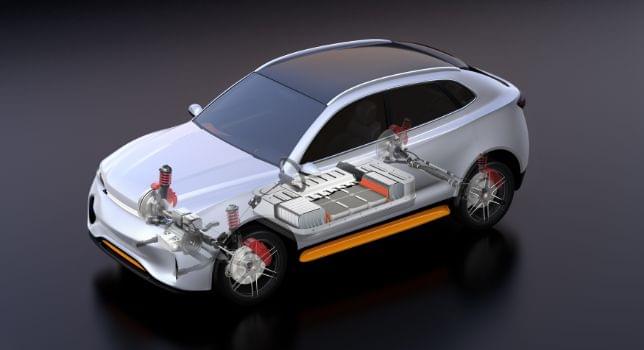

The global shift to electric vehicles (EVs) is often seen as a race for the best battery cell. Yet while cell chemistry matters, the long-term reliability of EVs is mainly affected by

wiring harnesses and

many complimentary parts.

The system's reliability depends on every component - from adhesives that attach modules, to

hoses, tubes, and seals that safeguard electronics from the elements.

For EV manufacturers and tier suppliers, validation isn't optional; it’s the non-negotiable insurance against failure. Our recent visit to the

Battery Show in Detroit gave us the opportunity to speak with engineers throughout the supply chain on how our services can support all of these critical components.

Managing Thermal Conditions and Sealing Performance

One of the challenges to battery longevity and performance is temperature fluctuation. Batteries need a good

thermal management system that keeps cells in an optimal range, regardless of ambient conditions or charging status. Cooling systems include various tubing, reservoirs, and pump assemblies running coolant that must be validated under pressure, vibration, and varying temperature conditions. In addition, as coolant fluids have changed, the materials of construction must also be validated to understand compatibility.

Seals and gaskets not only support all the fluid handling systems throughout the vehicle but also protect the battery compartment. Temperature variations and other environmental exposures can change physical property performance and lead to thermal runaway events or substantial moisture damage. Therefore, it is essential to test and validate their chemical compatibility, viscoelastic properties, and physical properties to minimize overall risks associated with each specific application.

Making the Connection

Wiring harnesses and connectors stretch throughout the EV connecting critical electronic and power systems. They see a wide variety of environmental conditions and experience vibrations and possible abrasion during their service life. Laboratory testing can validate these assemblies against any combination of these environmental factors from salt spray to temperature variations to material abrasion testing.

Where the Rubber Meets the Road

EVs are heavy. The battery packs alone can add hundreds if not thousands of pounds depending on the model, placing unprecedented demands on suspension systems and, most critically, tires. Some standard tires are not optimized to handle the immediate torque and sustained weight of an EV. At the same time, EVs are trying to optimize range, requiring tires with low rolling resistance.

Therefore,

Tire testing is crucial for manufacturers. They need to ensure not only that the tire's structural integrity can withstand constant heavy loads but also that the tread compound effectively maintains high traction without creating excessive rolling resistance or tread wear. All of this qualification work will require everything from compound studies to laboratory-based rolling resistance, force and moment, and uniformity testing to road proving ground evaluations including wet grip, handling, and tread wear.

Proving Performance in the Real World

While laboratory testing provides fundamental data, true confidence comes from system-level validation in the real world.

Cold, wintery environments can degrade battery life and challenge electronic systems and motors.

Cold soak chambers and a myriad of testing at

winter proving grounds can truly help OEMs and tier suppliers understand how their components stand up to the harshest environments. In the EV ecosystem, every complementary component is a critical part of validating and improving EVs and battery performance.

By working with professional testing companies like Smithers to validate the materials, assemblies, and systems that support the power source, manufacturers can guarantee longevity and reliability of future electric demands.