The global market for rigid plastic packaging is worth $220.2 billion in 2025, and is forecast to grow by 3.6% CAGR to $262.7 billion in 2030, according to the latest research from Smithers, the worldwide authority on the packaging industry.

A new expert market report from Smithers –

The Future of Rigid Plastic Packaging to 2030 – finds that improving recycling, managing volatile raw material costs, and integrating new technologies are among the top priorities for rigid plastic bottles, trays, tubs, pots and other packaging formats across the next five years.

lthough demand will slow in mature markets, especially Western Europe, this will be balanced by expansion of modern retail infrastructure and packaged goods consumption in developing economies.

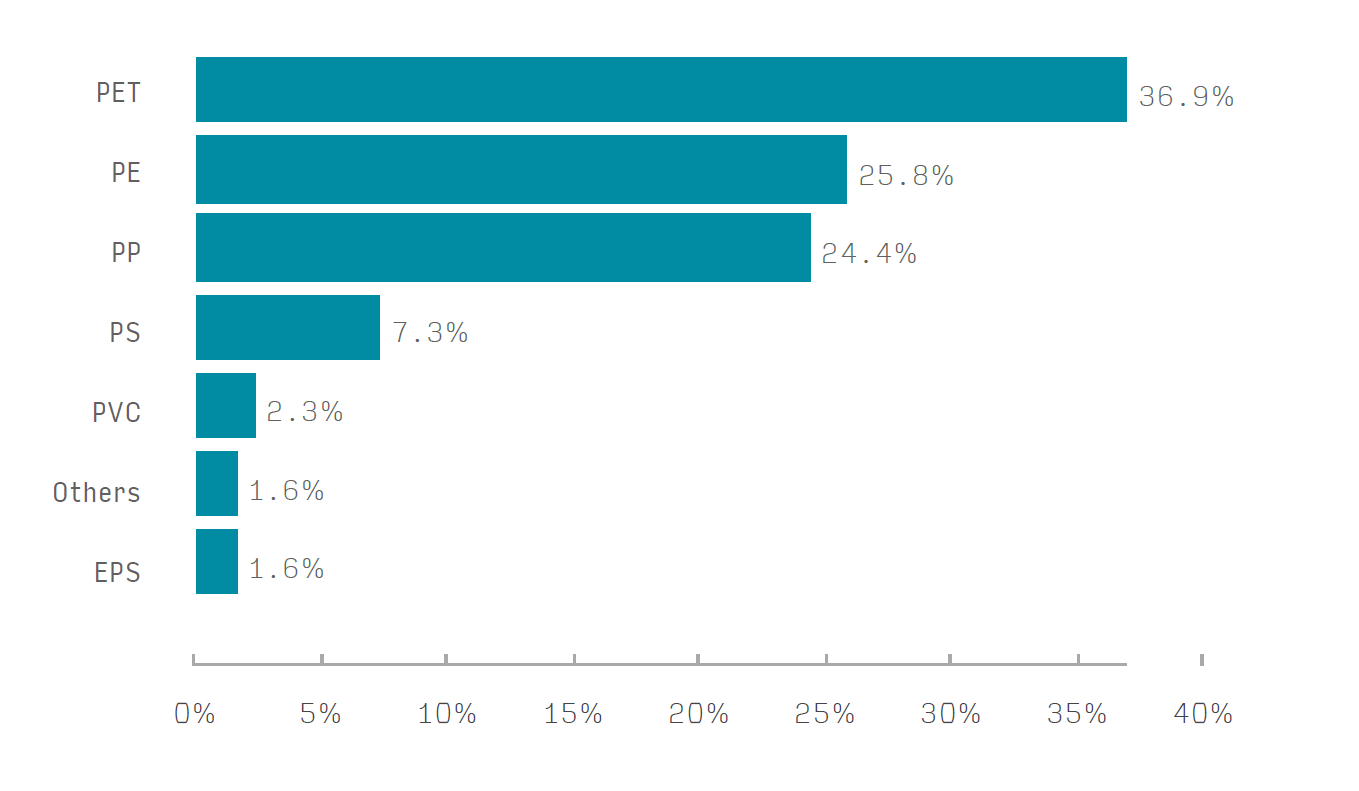

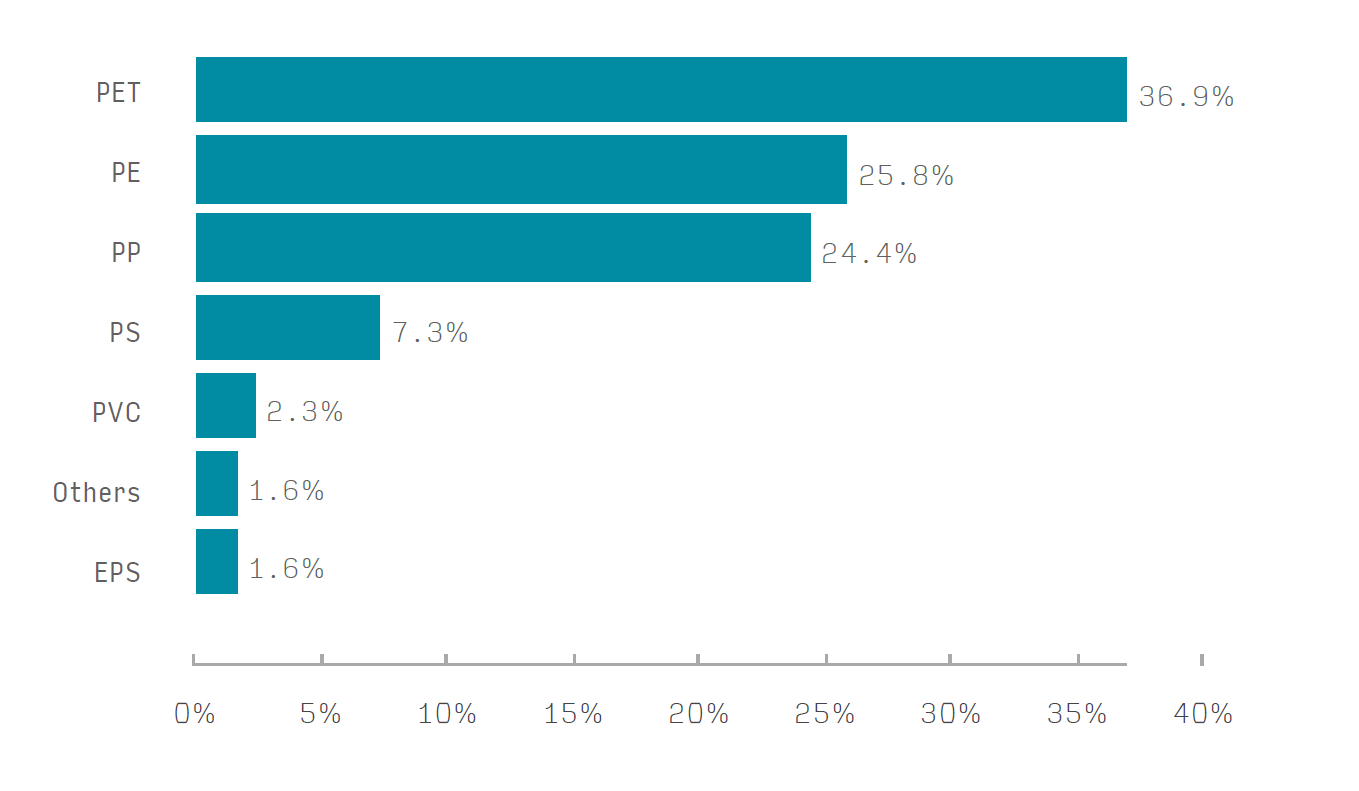

Across the Smithers forecast period, the volume of plastics used in rigid packaging will increase from 67.9 million metric tons in 2025 to 80.8 million metric tons in 2030. Polyethylene terephthalate (PET) remains the most widely used polymer. It accounts for 36.9% of world demand in 2025, ahead of polyethylene (PE), 25.8%; and polypropylene (PP), 24.4%. PET will grow its market share across the next five years, assisted by greater demand for bottled beverages, hot-fill food bottles and jars, ready-meal trays, pharmaceutical and personal care formats.

Smithers forecasts increased demand for rigid PP packaging as it proves a lower-cost option to both high-density PE and polystyrene (PS) in multiple injection molding applications. The polymer is increasing its market share in several food segments and the development of clarified PP grades and better processing technology will see these penetrate the blow molded bottle market further. While PE and PP are harder to recycle than PET, improvement is predicted to come on stream soon, including food-grade resins from the first generation of advanced (chemical) recycling lines.

There will be a wider use of mono-layer rigid plastic packs to improve recyclability across the sector. This will increase demand for coatings that can replicate the barrier performance previously delivered by multi-layer bottles for fruit juices, milk, wine and hot-fill foods.

In beverages, large bottle-making companies are shifting manufacturing to, or near to, major brand owner sites, thereby pooling expertise and reducing logistics costs. Beverage brand owners are increasingly bringing preform and bottle-blowing activities for PET bottles in-house, using blow-fill-cap processes. This eliminates the need for palletizing, banding, stretch wrapping, storage, shipping, depalletizing and conveying – which saves warehouse space and offers multiple cost efficiencies.

Global rigid plastic packaging: percentage share of consumption by material, 2025

Source: Smithers

The Future of Rigid Plastic Packaging to 2030 is available to purchase now from Smithers priced $6,750 (€6.350, £5,475).