3D Non-Contact Profilometry

Smithers have facilities to measure the three dimensional profile of packaging surfaces.The Proscan 2000A is a non-contact measurement instrument which allows non-destructive testing, whilst achieving precise and detailed analysis of the surface structure.

How it works

Light from a white light source is reflected by a beam splitter and transmitted along a fibre optic cable to the measurement head. The white light is focused through a lens with built-in spectral aberration and divided into different wavelengths of light. Each wavelength is focused at a slightly different height in the measurement range and only one wavelength of light is in focus at the given position of the object surface. The light is reflected back from the object and is transmitted back through the lens and fibre optic cable. The signal is then passed through the beam splitter and projected onto an optical pin hole which only allows the frequency of light in focus to pass through. The specific wavelength is detected when the incoming light is deflected by the spectrometer grating onto a CCD sensor. The signal is analysed and converted into a height measurement.

Applications

Profilometry is useful where the analysis of the surface is critical to the performance of the finished product. It can be used to characterise surface properties, such as roughness and curvature. Surface profiling can also be a valuable tool when investigating issues such as damage, or making improvements to the surface of a product. Typical applications have included the analysis of surface coatings, material defects and the curvature of components to investigate adhesive failure, as well as the following:

Typical applications have included the analysis of surface coatings, material defects and the curvature of components to investigate adhesive failure, as well as the following:

- 3D surface topography

- Dimensions - depth, step height, length & width

- Curvature

- Defect analysis - i.e. scratches

- Roughness parameters

- Line profiles

- Coatings

- Embossing

- Surface characterization.

Instrument specification

Instrument specification

- Nominal characteristics of system specified in BS EN ISO 25178-602: 2010

- High Resolution (see table below)

- Non-contact confocal chromatic probe

- Non destructive.

| Probe | Z-direction measuring range | Resolution |

| A | 12mm | 400nm |

| B | 400µm | 22nm |

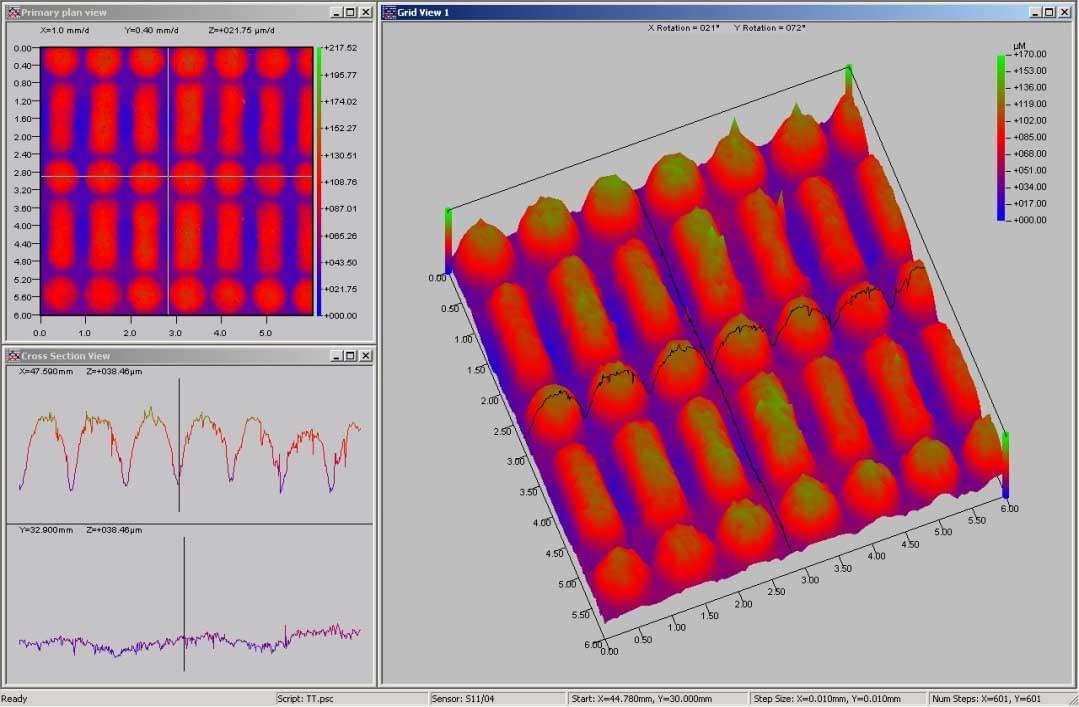

2D profile in XY axis (top left), 2D line profile in XZ and YZ axis (bottom left) and 3D embossing profile (right).

2D profile in XY axis (top left), 2D line profile in XZ and YZ axis (bottom left) and 3D embossing profile (right).