Perhaps the most important part of tire design is how the tire interacts with the road surface. It is within this interaction area (called the tire footprint or contact patch) that tire forces and moments arise and that wear occurs. Smithers has the tools and expertise to help engineers understand and optimize the tire contact patch. These include ink measurements of footprint shape and groove/void ratio, optical contact pressure measurement, and multi-axis measurements of footprint stress, motion, and frictional energy.

Tire Footprint Stress and Motion Analysis

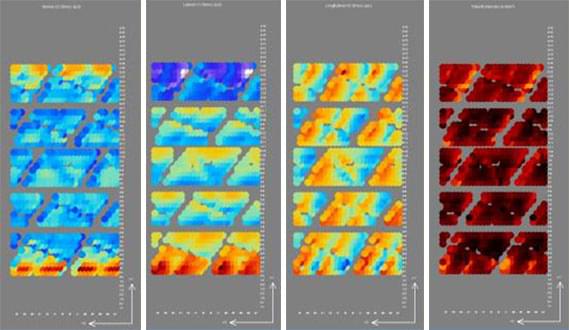

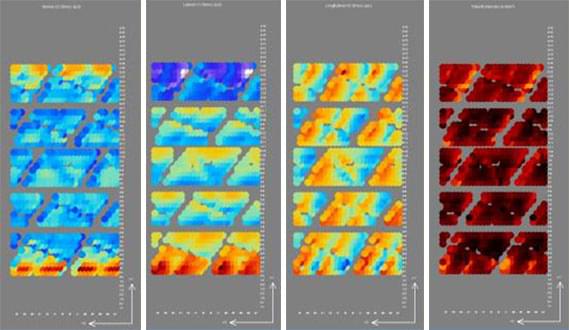

For in-depth study of footprint mechanics and understanding why tires wear, Smithers offers footprint stress and motion measurement. Footprint stresses and motions are measured by rolling a tire over an array of pins that measure forces and motions.

The pins measure not only contact pressure, but also lateral and longitudinal stresses and motions. The three images on the left show vertical, lateral, and longitudinal stress distributions for a rolling passenger tire, rolling to the left. From these measurements, footprint frictional energy intensity can be calculated for the same tire, as shown by the image on the left.

Figure 1: Stress distributions and footprint frictional energy intensity

Figure 1: Stress distributions and footprint frictional energy intensity

Typically, areas with higher footprint energy intensity will be faster wearing than areas of lower intensity, potentially leading to irregular wear of the tire. Understanding these effects can help the design engineer optimize a tire’s wear propensities.

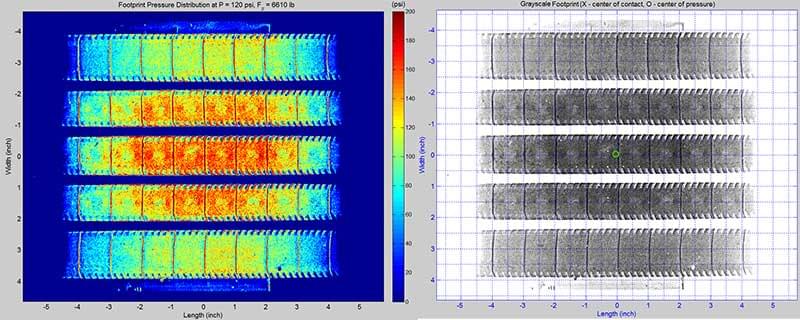

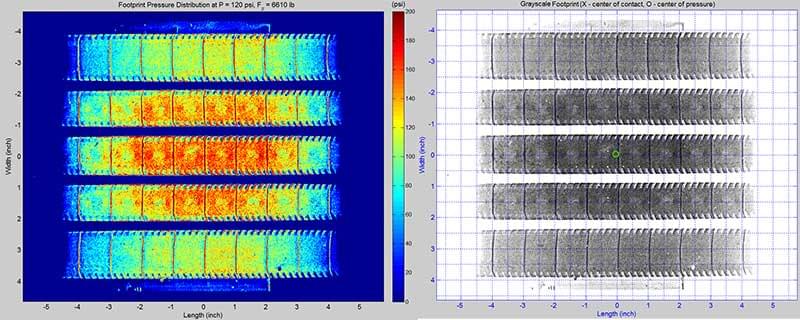

Optical Footprint Measurements

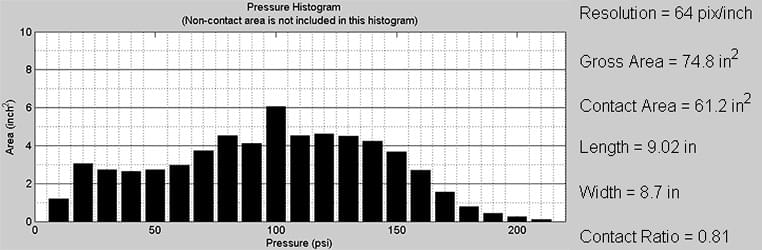

Smithers uses an optical footprint measurement system (glass plate method) that operates using the frustrated total internal reflection (sometimes referred to as FTIR) phenomenon. This method provides a high-resolution footprint map with the contact pressures at an accuracy comparable to that of piezo-resistive and capacitive footprint pressure measurement methods that normally provide much lower resolutions.

Figure 2: Optical footprint of a truck tire

Figure 2: Optical footprint of a truck tire

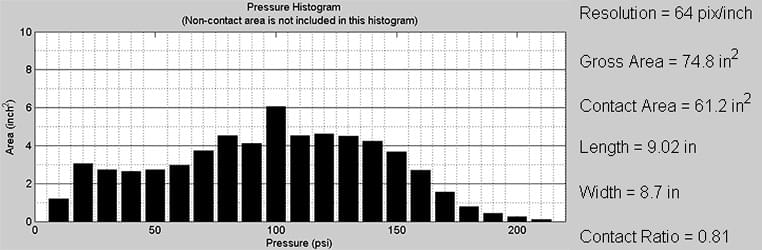

The optical footprints are used to calculate footprint shape, contact ratio, and normal contact pressure distribution. We also provide advanced data analysis and customized reports on your special request.

Figure 3: Typical calculations from the optical footprint

Figure 3: Typical calculations from the optical footprint

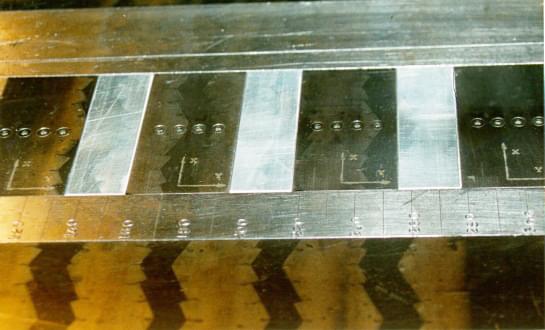

Ink Footprints

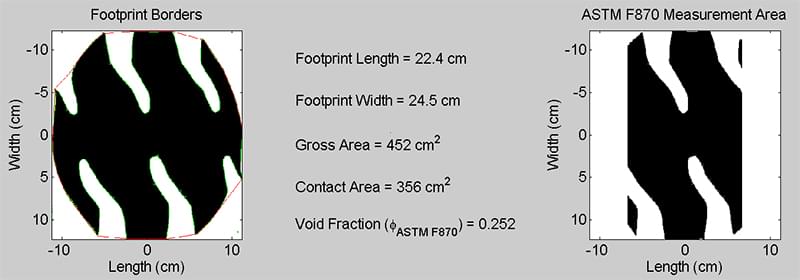

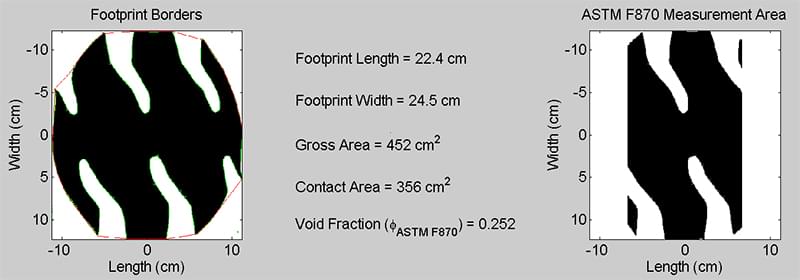

Smithers performs ink footprint measurements of small PC/LT tires as well as large OTR tires. Ink footprints are digitized by imaging/scanning and analysed to calculate length, width, gross and contact areas, and void fraction. Customized analysis is possible on special request.

Figure 4: Typical analysis using a digitized ink footprint

Figure 4: Typical analysis using a digitized ink footprint